BLOG

KATEGORİDEKİ DİĞER YAZILAR

Gas flow rate is the volume of gas passing through a given point in a given time. Gas flow rate calculations are widely used in process engineering disciplines. Flow rate calculations in chimneys are often difficult. Because chimneys vary in diameter along their length. Basic calculations can be applied to any gas. Gases are compressible and change in volume when pressurized, heated or cooled. Gas volume under a range of pressure and temperature conditions is not equivalent to the same gas under different conditions.

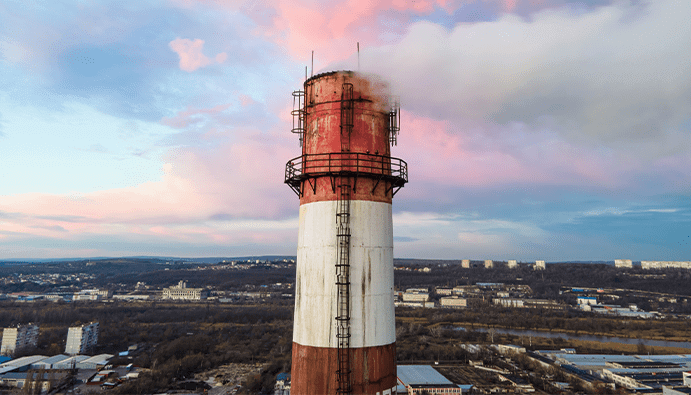

The gas flow rate is measured directly with different measuring instruments, independent of the effects of pressure and temperature. Measurements are related to the density of the material, and the density of gases depends largely on pressure, temperature and, to a lesser extent, composition. Flue gas is the gas released into the air through a chimney, which is a pipe or duct to convey exhaust gas from a furnace, stove, boiler or steam generator. The composition of flue gas is different depending on what is being burned, but in general it consists of air, carbon dioxide, water vapor and nitrogen. It also contains small amounts of a number of pollutants such as particulate matter, carbon monoxide, nitrogen oxides and sulphur oxides.

The velocity and flow rate of flue gas flows in chimneys vary mostly depending on the fuel composition, combustion power and burner air setting, chimney diameter and the temperature of the gas entering the chimney.

Measuring the gas flow rate and flow rate is important for controlling flue gas emissions and meeting environmental standards. These measurements are made for the following reasons:

Nanolab Laboratories Group continues to provide services within the scope of Determination of Velocity and Flow Rate of Gas Flows. We also provide services in Emission - Imission Measurements.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.