BLOG

KATEGORİDEKİ DİĞER YAZILAR

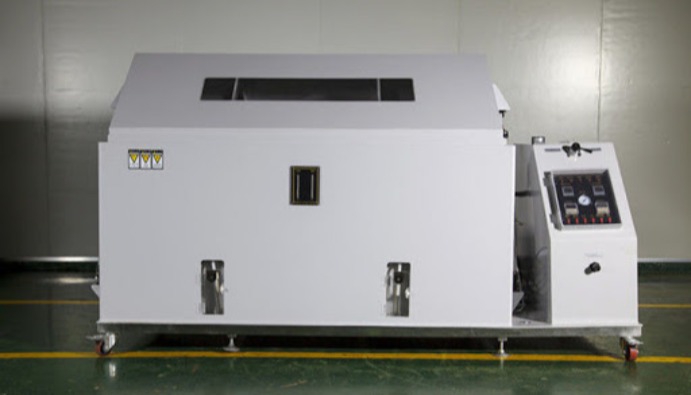

Climatic conditions and mechanical stress can affect various physical properties of products. Therefore, environmental testing is important to ensure both durability against external factors and to meet user requirements. Climatic conditions include factors such as temperature, humidity, ultraviolet (UV) rays, rain and wind, while mechanical stress includes loads, impacts and deformations caused by prolonged use.

Environmental flood testing simulates the different climatic conditions and mechanical stresses that products are exposed to during their lifetime; it is the identification of problems that may arise in the design or performance of a product, especially when exposed to extreme levels of weather conditions.

In general, environmental testing shows that your products have the build quality to perform perfectly, regardless of environmental conditions such as climatic conditions or vibration. During testing, potential weaknesses can be identified and product improvements can be initiated at an early stage.

Environmental testing also helps to demonstrate that your products comply with international regulations, facilitating access to global markets. Environmental testing also increases confidence in your products.

Nanolab Laboratories Group continues to provide services within the scope of Consumer Analyzes. We also provide services in Textile Analysis.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.