BLOG

KATEGORİDEKİ DİĞER YAZILAR

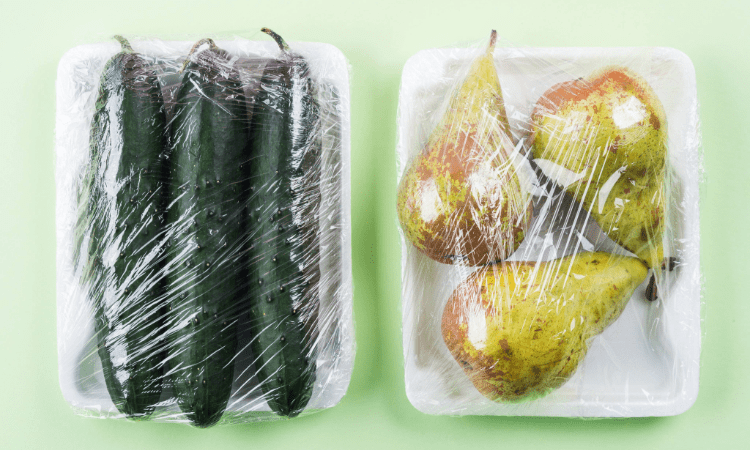

Food safety is an element that must be carefully protected at every stage from production to consumption. One of the most critical links in this process is the packaging material. Packaging not only protects the product from external factors, but also extends the shelf life of the food, minimizing the risk of microbial contamination, chemical contamination and physical damage.

Selecting appropriate packaging and analyzing it regularly is of great importance for consumer health. Migration tests, physical durability tests and chemical analyses should be performed, especially on packaging materials that come into contact with food. These tests determine whether any substance in the content of the packaging has migrated into food and whether this migration is within safe limits.

As laboratories that analyze packaging, we support companies to comply with legal regulations and increase brand reliability with the testing services we offer. It is also increasingly important to offer sustainable and environmentally friendly packaging solutions. With the right choice of materials, products that are both environmentally friendly and protect human health can be offered to the market.

Food safety depends not only on production conditions but also on the packaging materials used. Packaging that comes into contact with food plays a role in preserving the freshness of the product, extending its shelf life and protecting it from external factors. Therefore, factors such as health, suitability and durability should be carefully considered when choosing packaging.

The right packaging material should be chosen so that it does not interact with food and does not allow harmful substances to pass through. In particular, migration analysis of plastic, paper, cardboard or metal-based packaging should be carried out and the material's resistance to conditions such as temperature, humidity and light should be tested. The physical integrity of the packaging is also an important factor. Materials that tear or leak easily can increase the risk of product contamination.

As packaging analysis laboratories, we offer special test programs for companies. The compliance of the selected packaging with the relevant national and international food safety standards is examined in detail. Thus, manufacturers both fulfill their legal obligations and gain consumer confidence.

Nanolab Laboratories Group continues to provide services within the scope of Packaging Analysis.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.