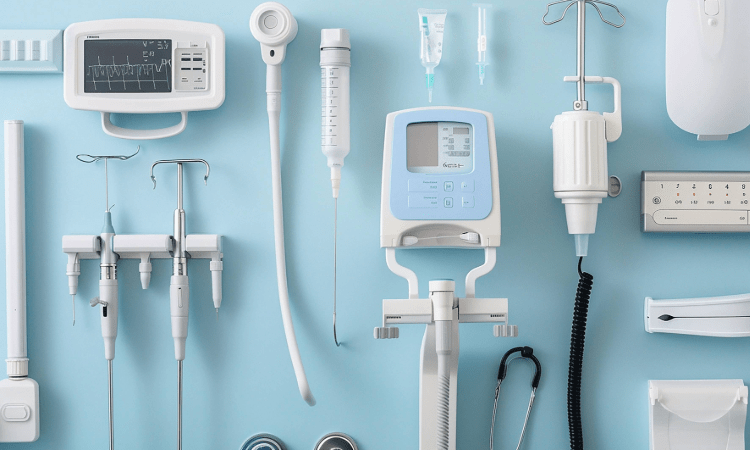

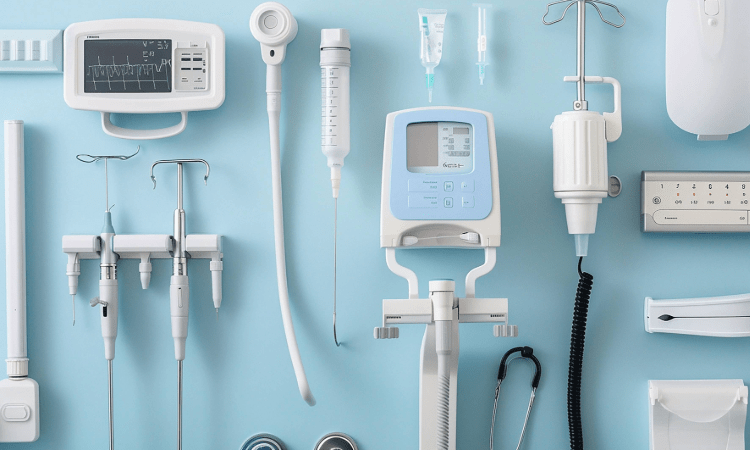

Medical Devices: Durability and Reliability Testing

Why are Durability and Reliability Tests Conducted?

The reliability and durability of medical devices is vital for the healthcare industry. As these devices have a direct impact on human health, they must undergo rigorous testing processes to ensure that their performance is long-lasting and reliable. Durability and reliability testing involves scientific approaches and techniques used to evaluate both the physical and functional characteristics of devices.

What is Durability and Reliability Testing?

Durability testing evaluates the resistance of devices to mechanical, chemical and environmental conditions.

Reliability tests analyze the extent to which the device's functionality is sustainable over time.

What are the Purposes of the Tests?

- To ensure user safety of the device.

- To ensure that it performs its functions correctly throughout its expected lifetime.

- To certify that the products comply with national and international standards.

1. Mechanical Tests

These tests evaluate the resistance of devices to physical stresses.

- Torque Test: Measures the durability of screw connections.

- Impact Resistance Test: Tests the device's resistance to situations such as drops or bumps.

- Abrasion Test: Determines the resistance to friction of the surface materials of the device.

2. Environmental Tests

It is performed to measure the adaptation of medical devices to various environmental conditions.

- Heat and Humidity Tests: The performance of the device is examined under extreme temperature or humidity conditions.

- UV Resistance Test: It is performed to prevent material degradation in devices exposed to sunlight.

- Accelerated Aging Test: It is a process applied to simulate long-term use of the device.

3. Electrical Safety Tests

These tests are applied to ensure the safety of electrical devices.

- Grounding Resistance Test: Evaluates the adequacy of safety measures against electrical leakage.

- Insulation Test: It is performed to prevent leakage of electric current to the outer surface of the device.

4. Chemical Resistance Tests

It examines the resistance of medical devices against disinfectants, sterilization chemicals and body fluids.

5. Biomechanical Tests

It evaluates the adaptability and durability of devices to human biomechanics. It is especially important for prostheses and implants.

6. Reliability Tests

- Cyclic Load Test: Tests whether the device maintains its functionality in repetitive usage scenarios over a period of time.

- Long Term Performance Test: Measures how long the device can remain stable in continuous use.

What is the Importance of Tests?

- Patient Safety: Testing ensures that devices do not put the user at risk with unexpected failures.

- Regulatory Compliance: Compliance with standards such as ISO, CE and FDA is key to market presence.

- Quality Control: Guarantees that every device coming out of production is of high quality.

- Cost Savings: Long-lasting devices provide economic benefits for both manufacturers and users.

Nano-lab Laboratories Group continues to provide services within the scope of Durability and Reliability Tests in Medical Devices. We also provide services in Chemical Characterization.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.