TOC Analysis in Cleaning Validation: Cleaning Verification

What is TOC (Total Organic Carbon)?

What is Cleaning Validation?

Cleaning validation is a critical step in many industries, from medical device manufacturing to pharmaceutical production, to ensure that products are contamination-free and safe. Especially in industries such as pharmaceutical manufacturing, biotechnology and medical device manufacturing, the effectiveness of cleaning processes must be validated to meet high quality and safety standards.

Cleaning validation ensures that all equipment used in the production process is effectively cleaned using appropriate methods to ensure safety and quality control in production facilities. The main objective of cleaning validation is to ensure that no residues remain or are removed from the production equipment and area. Cleaning Validation is also performed to determine the effectiveness of cleaning after cleaning the equipment.

The Role of TOC Analysis in Cleaning Validation

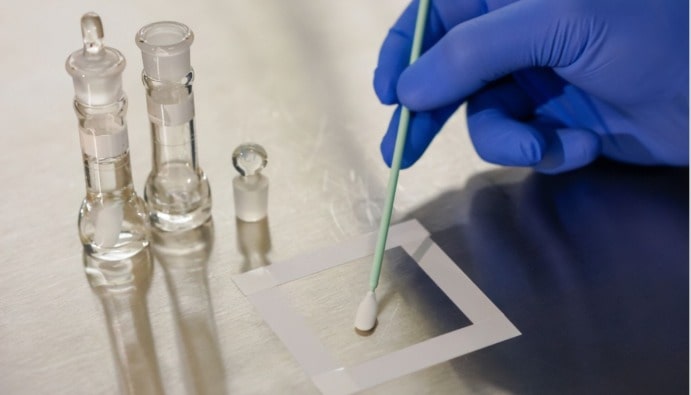

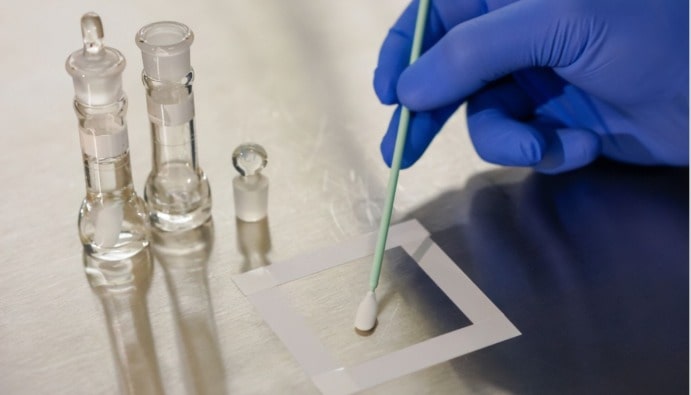

TOC analysis is used to detect organic substances, especially those that remain on cleaned surfaces or equipment. Cleaning involves the removal of microorganisms, chemicals and other contaminants from machines, equipment, pipes and other surfaces used in production processes. In this context, TOC becomes an important parameter in determining the effectiveness of cleaning processes.

Cleaning validation is achieved through the following steps:

- Cleaning Process Design and Implementation: First, the cleaning process must be properly designed and implemented. This includes the cleaning chemicals used, cleaning methods (e.g., manual cleaning, autoclaving, in-line cleaning) and duration.

- Monitoring and Testing of Cleaning Performance: After the cleaning process is implemented, it is checked by TOC analysis whether organic residues remain on surfaces or equipment after the cleaning process.

- Verification and Validation: The cleaning process must be validated with specific parameters. TOC analysis allows organic residues to be assessed against maximum permissible levels.

Benefits of TOC Analysis in Cleaning Validation

- Contamination Detection: TOC analysis determines the amount of organic matter left on surfaces or devices after cleaning. If the cleaning process is inadequate, high levels of organic carbon are observed, indicating that the contamination has not been removed.

- Fast and Accurate Results: TOC testing is a technique that provides fast results and can detect organic contaminants with high sensitivity. This enables rapid assessment of production processes.

- Verify Equipment and Surface Cleanliness: TOC analysis is used to verify the cleanliness of equipment, especially those used during production. Checking the adequacy of cleaning improves product quality and safety.

- Reducing Chemical and Microbial Risks: Complete removal of organic residues during cleaning reduces both chemical residue risks and microbial contamination risks. This is critical for product safety and patient health.

- Compliance with Regulatory Requirements: In many industries (especially in the pharmaceutical and medical device sectors), cleaning validation is a regulatory requirement. TOC analysis is a tool used to comply with these requirements. TOC tests to prove the validity of cleaning processes can be requested by regulatory bodies.

Nanolab Laboratories Group continues to provide services within the scope of Medical Device Analysis.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.