Turbine Oil Analysis: Performance and Equipment Life

Turbine Oil Tests

Turbine Oil Analysis

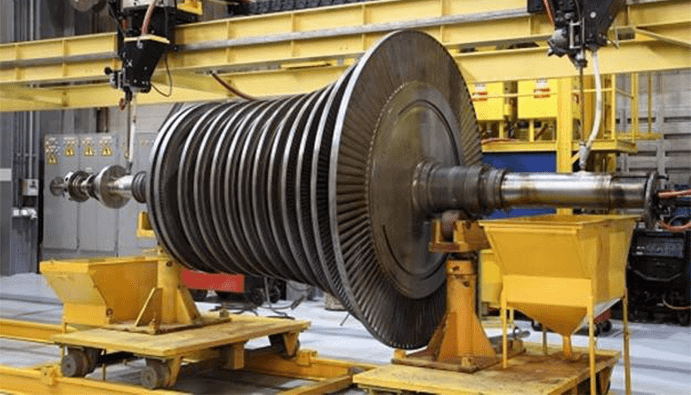

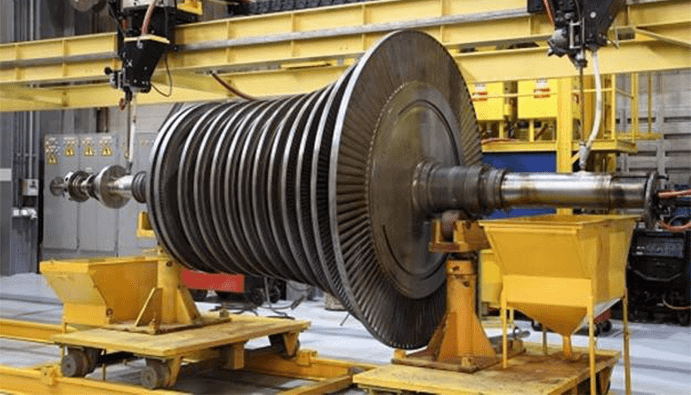

A turbine can be expressed as a mechanism consisting of a shaft and blades on it and used to convert the energy of a fluid into kinetic energy. Turbine oil is used to increase the efficiency of turbines and to ensure trouble-free operation. Turbine oils play a role in the uninterrupted operation of energy generation and industrial systems. These lubricants prevent wear of the equipment and extend the life of the systems by providing thermal and oxidative resistance. Turbine oil analysis is an important tool for monitoring the performance of these oils, increasing equipment life and preventing costly failures.

What are Turbine Oil Conformity Tests?

- Kinematic Viscosity at 40 °C

- Degree of Purity

- TAN (total acid number)

- FTIR - oxidation, water

- ICP-OES - Elemental content: wear metals, impurities, oil additives

- Assessment of oil and turbine condition

Depending on the results of the tests; the quality of the oil can be determined, its suitability can be determined and the proper use of the turbines can be kept under control.

Importance of Turbine Oil Analysis

- Equipment Protection and Performance: Turbine systems operate under high temperatures and heavy loads. The proper viscosity and oxidation stability of the oil ensures the safety of the equipment. Prevents wear and corrosion on metal surfaces.

- Failure Prevention: Acting as an early warning system, oil analysis detects problems in the system at the initial stage. It prevents unexpected downtime and costly repairs.

- Optimizing Oil Change Intervals: Monitoring the lifetime of the oil prevents unnecessary oil changes. This saves costs and reduces environmental impact.

- Energy Efficiency: Clean and functional oil allows turbines to operate with less energy consumption.

Turbine Oil Analysis Methods

- Spectrometric Analysis: Used for monitoring wear metals, contamination and additives. Methods such as ICP-OES or AAS are preferred.

- FTIR Spectroscopy: Analyzes oxidation, nitration and water content.

- Karl Fischer Titration: Used to measure the amount of water in the oil.

- Rotating Pressure Vessel Oxidation Test (RPVOT): Measures the oxidation resistance of the oil.

- Particle Count: Particle density in oil is evaluated according to ISO standards.

Nanolab Laboratories Group continues to provide services within the scope of Turbine Oil Analysis. We also provide services in Mineral Oil Analysis.

Contact us for more information.

You can follow us on LinkedIn for up-to-date news and posts about our services.

Follow our Instagram account to be informed about our latest blog posts.